Your trusted project solution partner.

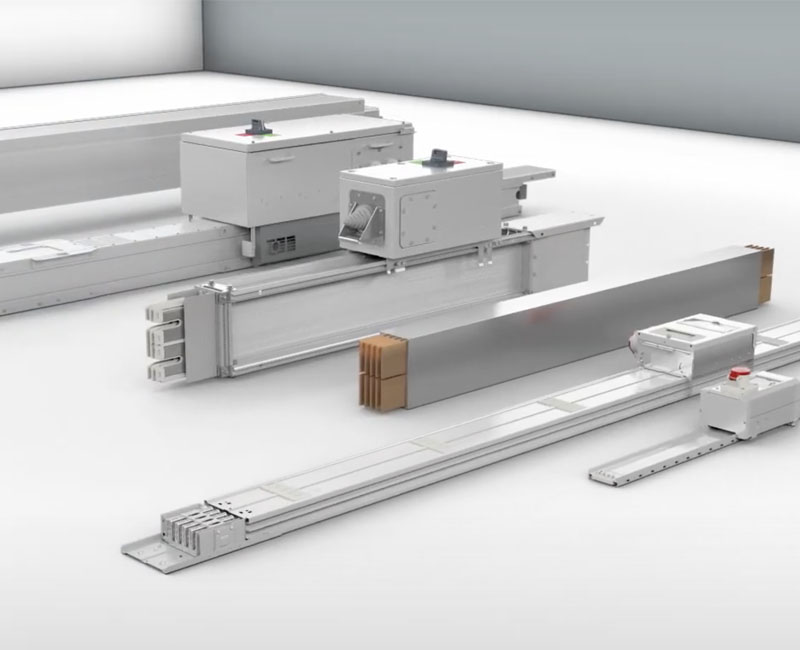

HAF Plastics meticulously meets the project-based needs of its customers in all of its product design, mold design, planning, production and delivery processes.

Custom Solutions

Cross-industry diversity, our range of applications

Our team of specialists, engineers and project managers will assist you from the beginning of your project to the final delivery.

The needs and demands of our customers are our first and foremost priority when developing a concept.

Material selection is made for each project specifically considering the functional performance, aesthetic effect, texture and the color.

Our experienced technical team are ready to share their experiences and improve the design.

Quality control is managed with latest technology. Finished goods are controlled with video measuring system and camera control system.

We are comitted to improving the sustainability

+1

The plastic profiles produced by HAF Plastics can be recycled 100%. Our aim is to keep the environment clean from plastic pollution.

+2

HAF Plastics values the confidentiality, reliability, justice and equality for employees, suppliers and customers.

Right design starts with the selection of right raw materials, Lghting, Engineering Plastics, Commodity Plastics!

ServicesLatest News from us

News & Insights

-

The Injection Molding and Design expo is an exciting new free-to-attend tradeshow.

Expo focused exclusively on injection molding, the two-day event brings together the complete North American supply chain, from part and mold design, through process optimization and automation, to finishing and assembly. MAY 25-26, 2022 - DETROIT, MI, USA

-

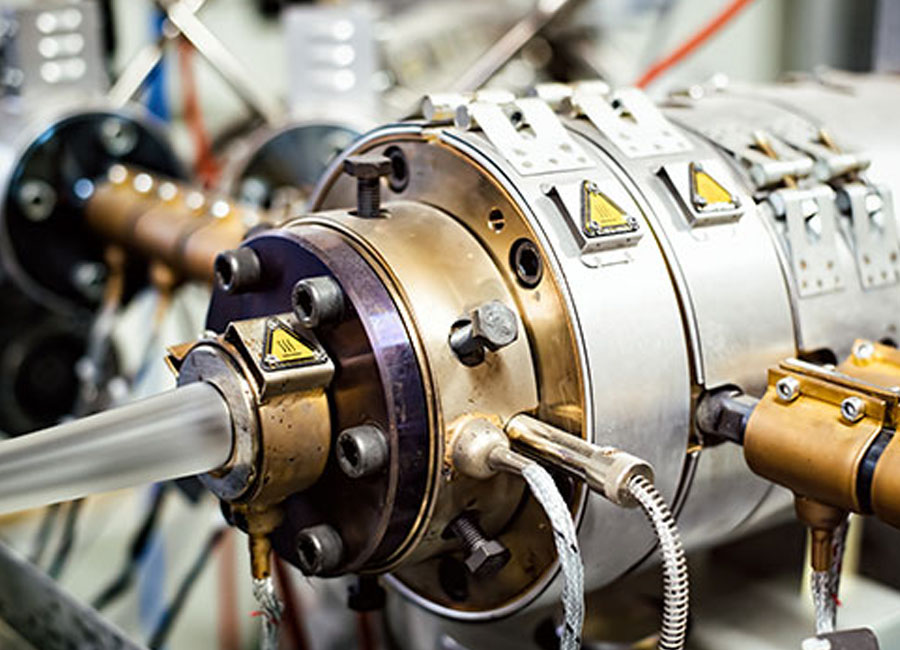

High-performance materials and additional machining are increasingly requested by operators in the cooling industry.

Refrigerator doors, body profiles and their internal lighting units must guarantee excellent thermal insulation and be made of high performance materials. We produce custom extruded plastic profiles to help the commercial cooling systems operate efficiently. Plastic profiles produced using cutting-edge technology plastic extrusion lines will help to increase the performance of your products and reduce production and service costs.

-

Recognizing the need is the primary condition for design.

We work with our clients to develop and manufacture optimal profiles for their needs, from the planning stage of the project through the manufacturing of tools, to the beginning of manufacturing. Whether it’s lenses or embossed or colorless profiles, as needed, our qualified plastics engineers, experienced design team, and in-house tool manufacturing guarantee fast and cost-effective solutions.